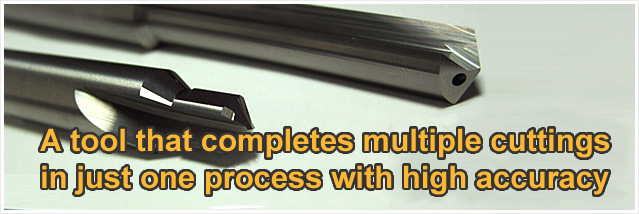

Burnishing drill bit

This tool is widely used in precision parts machining of iron and aluminum cast materials and ideal for strict tolerance requirements for hole diameter, circularity, cylindricity, and surface roughness. Our custom-made tools have designing advantages that can incorporate complex steps in one tool, enabling delicate multi-step contour shaping in just one work process.

With a point angle of 118 degrees, similar to other drill bits but not like a burnishing reamer, this burnishing drill bit requires no pilot hole; it can directly perform semi-finishing and finishing of multi-step hole machining in just one work process.

We provide the tools to hydraulic components processing companies (which process parts for hydraulic valves, motors, pumps, cartridge valves, etc.) for their machining of important hydraulic cartridge valves.

Other customers include components manufacturers in the following industries.

| Precision reduction gears for industrial robots, machine tools, and joints for industrial robots for the semiconductor industry

Railway vehicle equipment, automotive equipment, marine equipment, commercial aircraft, industrial equipment |

Burnishing drill bit

Cutting tools for cast iron-based materials (Fe-C alloy) and aluminum alloy machining

Straight-fluted, multi-step burnishing drill bit

This straight-fluted burnishing drill bit is for machining hydraulic valves.

With the advantages of straight flutes, the tool performs complex multi-step processing according to the shape of the workpiece.

You can use the tool after drilling a pilot hole and satisfy all the tolerance requirements of drawing in just one process.

High-feed twist burnishing drill bit

This burnishing drill bit is designed for aluminum machining.

The twisted flute discharges swarf upward, eliminating damage to the tool by clogged swarf and enabling high feeding.

In addition, the positive edge with twisted flutes reduces cutting resistance, eliminating workpiece deformation caused by cutting heat at high feed and enabling highly efficient machining.

Burr-free burnishing drill bit

Ductile materials prone to work-hardening such as aluminum alloy often create burrs, blunting edge quality.

Burrs are created with progressing cutting edge wear. The burnishing drill bit with a pilot edge enables 3-step machining, eliminating edge wear and inhibiting burr creation.

The burr-free burnishing drill bit can perform rough, semi-finishing, and finishing machining with just one tool.

Introduction of burnishing drill bit

Multi-step burnishing drill bit

|

Taking advantage of the easy shape of straight-fluted types, this tool can complete semi-finishing and finishing of complex multi-step holes in just one work process.

Difficult processing, such as bends, off center, and concentricity, requires delicate work. Using a burnishing drill bit and reamer with a guide at the cylindrical section can achieve higher machining accuracy than by using a conventional twist drill in such conditions. The tools are all-in-one types and the concentricity difference is within 5 microns for each step. |

Twist-fluted burnishing drill bit

|

The twist-fluted drill bit solves the weakness of straight-fluted drill bits, swarf clogging, by twisting its flutes. In the twist-fluted design, there are some design restrictions in stepped-edge design that is affected by the flutes. |